Counterbalance Forklift Training: Courses, Safety, and Compliance

What is a Counterbalance Forklift?

A counterbalance forklift is a type of powered industrial truck that has a counterweight at the back of the vehicle to offset the load being lifted by the two forks extending from the front. This design allows the forklift to be used both indoors and outdoors and enables operators to maneuver the vehicle to the exact position of the load they’re trying to move.

Counterbalance forklift training is commonly used in a variety of settings, including warehouses, distribution centers, and manufacturing facilities. They’re popular because of their exceptional stability, even during cargo transport. However, if overloaded, the forklift can tip over, causing damage to persons and property.

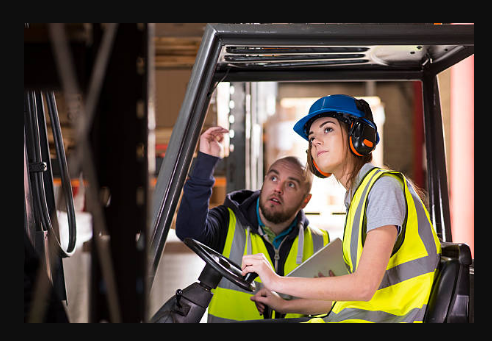

The Importance of Counterbalance Forklift Training Explained!

Training for counterbalance forklifts is vital for anyone looking to operate this type of machinery. In fact, it’s a legal requirement to undergo training before operating a counterbalance forklift truck. The training courses ensure that operators understand the equipment they’re using, its limitations, and how to operate it safely.

The training courses range from novice and experienced operators to refresher courses. A novice course will typically take five days, an experienced operators’ course is three days, and a refresher and test will take one day. Once you’ve completed the course, you’ll be awarded an operating card and certificate. The Trained Operator Passport Scheme (TOPS) will be updated to show your new training.

It’s important to note that forklift training is simply a course and doesn’t provide you with a license. You don’t need a driving license to complete the training, but you must be over 18 years old to do so.

How to Operate a Counterbalance Forklift — Forklift Licence

When operating a counterbalance forklift, it’s crucial to understand the vehicle’s unique design. The forklift includes a fulcrum front axle mechanism, a counterweight at the rear of the vehicle, and an additional counterweight with an additional fork load. The fulcrum is the main “pivot point” of the truck, and the front axle provides stability between the loaded weight and the rear counterbalance.

To operate a counterbalance forklift safely, operators need to be aware of all these attributes. They should understand the correct way to operate the vehicle, how to position the forks correctly, and how to maneuver the forklift safely.

Types of Counterbalance Forklift Training

There are several types of counterbalance forklift training available,including:

Novice Courses in UK

Novice courses are designed for individuals with little or no experience operating a forklift. These courses provide comprehensive training on the basics of operating a counterbalance forklift, including safety procedures, pre-use checks, and maneuvering the vehicle.

These courses typically take five days to complete, and upon successful completion, individuals will receive an operating card and certificate.

Experienced Operator Courses

Experienced operator courses are designed for individuals who have previously operated a counterbalance forklift but need to refresh their skills or update their training. These counterbalance forklift courses cover advanced topics, such as load distribution and stability, and are typically three days long.

Upon successful completion, individuals will receive an operating card and certificate.

Refresher and Test Courses

Refresher and test courses are designed for individuals who need to update their existing training or have let their training lapse. These courses are typically one day long and cover all the essential topics needed to operate a counterbalance forklift safely.

Upon successful completion, individuals will receive an operating card and certificate.

Counterbalance Forklift Safety and Compliance: Forklift Licence

Counterbalance forklifts can be dangerous if not operated correctly. That’s why it’s essential to undergo training to ensure you’re compliant with regulations and operating the vehicle safely.

OSHA standard 1910.178 defines the safety, training, and operational guidelines for all powered industrial trucks, including counterbalance forklifts. Training is required for all operators, and employers must provide OSHA compliant training and certification.

Failure to comply with regulations can result in significant fines and penalties. In fact, several companies have been audited and fined over $100,000 for safety violations related to their counterbalance forklift training programs.

Why Choose 2 Start for Counterbalance Forklift Training?

2 Start offers comprehensive counterbalance forklift training courses that cater to all experience levels and budgets. With high pass rates and a 4.9-star Google review rating, you can be sure that our courses provide students with the best training environment to gain their B1 Counterbalance operator certificate.

Our team of highly skilled forklift instructors provides all the theory and practical-based training required to operate a counterbalance forklift safely. We’ll walk you through all the steps you need to both explain and demonstrate throughout your training and your final assessment test.

Call our advisors at 02392 123 555 to speak with our experienced team. We’re available Monday through Friday from 7:00 am to 5:30 pm.

Conclusion: Top Counterbalance Forklift Courses

In conclusion, counterbalance forklift training is essential for anyone looking to operate this type of machinery. It ensures that operators understand the equipment they’re using, its limitations, and how to operate it safely. There are several types of training available, including novice courses, experienced operator courses, and refresher and test courses.

To ensure compliance with regulations and safety in the workplace, employers must provide OSHA compliant training and certification. Failure to comply can result in significant fines and penalties. Choose 2 Start for comprehensive counterbalance forklift training courses that provide all the theory and practical-based training required to operate a counterbalance forklift safely.

Comments

Post a Comment